2000-1817.45

The 2000-1817.45 component is essential to the operation of many devices and machines. As a vital part of equipment, it often requires replacement due to regular wear and tear or to enhance overall performance. To ensure that machinery operates smoothly and efficiently, it is important to carry out proper maintenance and replace the 2000-1817.45 at appropriate intervals. Although the replacement process can be complex, it is entirely feasible with the right tools and guidance.

This detailed guide is designed to lead readers through the complete process of replacing the 2000-1817.45 component. It encompasses an understanding of the component’s role, necessary preparation, techniques for removal, installation steps, and checks to perform post-installation. By adhering to this guide, users can approach the replacement process with confidence, promoting optimal performance and extending the lifespan of their equipment.

Understanding The 2000-1817.45 Component

What Is The 2000-1817.45?

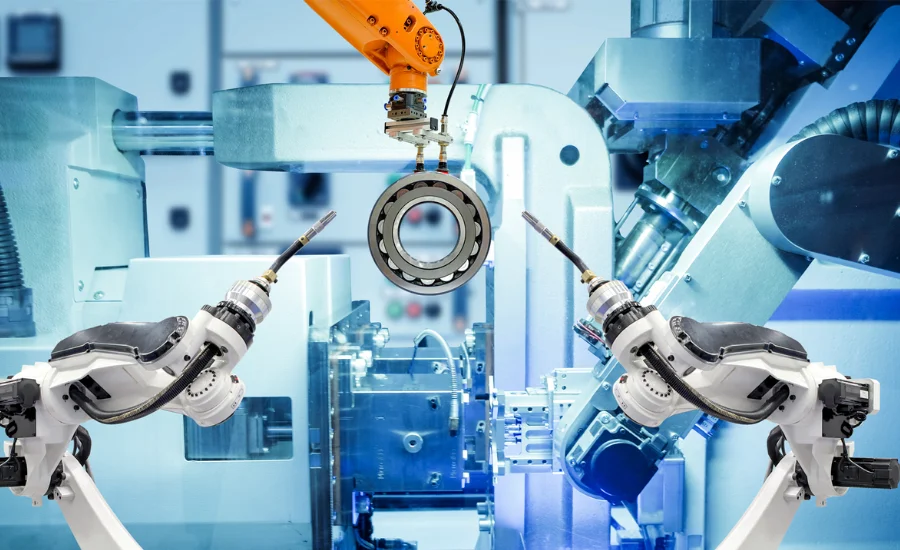

The 2000-1817.45 component is essential for the effective operation of a wide range of machinery and systems across multiple industries. Renowned for its robustness and dependability, this part is vital for ensuring that equipment functions correctly. However, like all mechanical parts, it is prone to deterioration over time due to regular use.

This component significantly influences the overall performance of the machinery in which it is integrated. Built to endure considerable stress and pressure, the 2000-1817.45 is particularly well-suited for challenging operational environments. Although its specific function may differ based on the system it serves, it generally plays a key role in enhancing the smooth operation and efficiency of the equipment.

Original Equipment vs. Aftermarket

When considering the replacement of the 2000-1817.45 component, users typically have two primary choices: Original Equipment Manufacturer (OEM) parts or aftermarket alternatives. Every choice has advantages and things to keep in mind of its own.

OEM parts are produced by the original equipment manufacturer and are specifically crafted to meet the precise specifications of the original component. While they often come with a higher price, they provide reliable performance and a perfect fit. OEM parts are usually the recommended choice for essential components and safety-related parts, ensuring optimal performance and compatibility with the existing system.

In contrast, aftermarket parts are manufactured by third-party companies and can offer potential cost savings along with greater availability. Some aftermarket components may match or even surpass the quality of OEM parts, but others might fall short of established standards. It’s vital to conduct thorough research and select reputable aftermarket manufacturers if you choose this route.

Ultimately, the decision between OEM and aftermarket parts hinges on several factors, including budget constraints, warranty implications, and the specific needs of the equipment. In some instances, using aftermarket components could void existing warranties, so it’s important to review the terms and conditions before making a final choice.

Common Issues And Wear Signs

Like all mechanical components, the 2000-1817.45 is susceptible to various issues and wear as time goes on. Identifying the signs of deterioration or potential malfunctions is essential for ensuring timely maintenance and replacement.

Common issues associated with the 2000-1817.45 include:

Leaks: One of the most prevalent issues associated with the 2000-1817.45 component is the occurrence of leaks, especially at the seals and gaskets.

Reduced Performance: A significant drop in the efficiency or output of the machinery could signal problems with the 2000-1817.45.

Unusual Noises: The presence of grinding, squeaking, or other irregular sounds during operation may indicate wear or damage to the component.

Increased Vibration: Excessive vibrations within the machinery might suggest that the 2000-1817.45 is malfunctioning or has become loose.

Visual Wear: During inspections, any visible signs of wear, including cracks, corrosion, or deformation, may be evident on the component.

To avoid more extensive damage, it is crucial to conduct regular inspections and maintenance checks. Following the manufacturer’s recommendations for maintenance intervals and replacement timelines is advisable to guarantee the optimal functioning and longevity of the 2000-1817.45 component.

By comprehending the characteristics of the 2000-1817.45, the available replacement options, and the common issues to monitor, users can make well-informed decisions regarding maintenance and replacement. This proactive approach will ultimately enhance the life and efficiency of their equipment.

Step-by-Step Removal Process

Removing the 2000-1817.45 component necessitates meticulous attention to detail and adherence to established procedures. This section provides a detailed overview of the essential steps for safely extracting the old component from the system.

Disconnecting Electrical Connections

Before initiating the removal of the 2000-1817.45 component, it is essential to disconnect all associated electrical connections. This precaution not only ensures safety but also helps avoid potential damage to both the component and the surrounding systems.

These connections may consist of wiring harnesses, connectors, or individual wires. It is vital to document the configuration and connection points to streamline the reassembly process later on.

When disconnecting the electrical connections, employ the correct tools, such as needle-nose pliers or a specialized connector removal tool. Carefully grasp the connector and pull it straight out, taking care to avoid any twisting or bending motions that could compromise the integrity of the pins or sockets.

For connectors that feature locking mechanisms, make sure to disengage the lock before attempting to remove the connector. Some connectors may have tabs that need to be pressed or levers that require lifting in order to release the locking mechanism properly.

Removing Mounting Hardware

After ensuring that all electrical connections have been properly disconnected, the next step involves removing the mounting hardware that secures the 2000-1817.45 component in place. This process generally requires detaching bolts, nuts, or other fasteners that hold the component to its mounting surface.

Before proceeding, it is advisable to clean the area surrounding the mounting hardware. This precaution helps prevent any debris from entering the system during the removal process. Utilize an appropriate cleaning solution along with a lint-free cloth to thoroughly wipe down the area.

Next, determine whatever kind and size of fasteners were utilized to keep the 2000-1817.45 in place.. The tools you may need for this task can include socket wrenches, Allen keys, or Torx drivers, depending on the specific hardware in use. It is essential to select the correct tool size to prevent stripping or damaging the fasteners.

As you remove the mounting hardware, make sure to keep a record of the order and location of each fastener. This will be invaluable during reassembly, ensuring that the new component is aligned correctly and securely installed.

Extracting The Old Component

After disconnecting the electrical connections and removing the mounting hardware, the final step involves carefully extracting the old 2000-1817.45 component from its designated position. This step necessitates meticulous handling to avoid causing any damage to surrounding components or the mounting surface itself.

Before you begin the extraction, it’s important to inspect the area thoroughly for any remaining connections or obstructions that could impede the removal process. In certain situations, you may need to temporarily relocate additional components or brackets to gain improved access to the 2000-1817.45.

To loosen the component from its mounting position, gently wiggle it back and forth. If the component appears to be stuck due to corrosion or residue buildup, applying a penetrating oil can assist in loosening it. Allow the oil to penetrate for a few minutes before attempting to remove the component again.

As you proceed to extract the 2000-1817.45, be cautious of its weight and size. For larger or heavier components, it may be beneficial to enlist the help of an assistant to support the weight during the removal process, thus minimizing the risk of damage or injury.

Once the component is adequately loosened, carefully lift it from its position, ensuring that you avoid bumping or scraping against nearby parts. Designate an appropriate area for placing the old component, ensuring you follow applicable environmental guidelines for proper disposal or recycling.

By adhering to these detailed instructions for disconnecting electrical connections, removing mounting hardware, and extracting the old component, you can effectively and safely remove the 2000-1817.45 from your system. This step sets the stage for the subsequent installation of the new component, which will be addressed in the following section of this guide.

Installing The New 2000-1817.45

Installing the new 2000-1817.45 component is a vital part of the replacement procedure. This stage demands careful precision and meticulous attention to detail to guarantee the system’s optimal performance and extended lifespan.

Proper Positioning And Alignment

Ensuring the correct positioning and alignment of the new 2000-1817.45 component is essential for its effective functionality. Begin by gently placing the new part in its intended spot, making sure it fits comfortably without any undue pressure on the connections. Utilize the reference points from the previous component’s installation to aid in this process.

To attain optimal alignment, it is crucial to take into account factors such as caster, camber, and toe. Caster refers to the angle of the steering axis as viewed from the side, while camber describes the inward or outward tilt of the wheel when observed from the front. Meanwhile, toe indicates whether the wheels are angled inward or outward when viewed from above.

For accurate alignment, employ a tape measure to assess the distances between specific points on the component. Measure from a consistent location on each side, such as a defined tread pattern, to guarantee precision. After taking these measurements, compare the front and rear distances to identify any necessary adjustments.

Securing The New Component

After ensuring that the 2000-1817.45 component is properly positioned and aligned, the next step is to secure it firmly in place. Begin by reinstalling any mounting hardware that was taken off during the removal process. This typically includes bolts, nuts, or other fasteners that secure the component to its mounting surface.

When fastening the mounting hardware, it’s essential to adhere to the manufacturer’s specified torque requirements. Applying too much torque can damage the component or its mounting points, while insufficient torque may result in the component becoming loose during operation. To achieve the correct tightness, utilize a torque wrench for each fastener.

If the 2000-1817.45 is part of a system that necessitates fine adjustments, such as a front-end alignment, further modifications may be required. This might involve loosening jam nuts on the tie rods and turning the tie rod to adjust the toe-in or toe-out. After completing any necessary adjustments, make sure to securely retighten all adjustable components.

Reconnecting Electrical Systems

The final stage of installing the new 2000-1817.45 component involves reconnecting all associated electrical systems. This step requires careful attention to detail to ensure that every connection is secure and properly aligned.

To begin, locate the different electrical connections that are connected to the 2000-1817.45. These connections might include individual wires, connectors, and wiring harnesses. If you took notes or photos during the disconnection phase, refer to them to help restore each connection to its correct position.

When reconnecting the electrical systems, prioritize safety. Always ensure that the power is turned off at the main electrical service panel before proceeding. This precaution is vital to avoid any risk of electric shock or damage to the new component.

As you reconnect each electrical component, check that all connections are tight and secure. Loose connections can result in intermittent operation or complete system failures. For connectors equipped with locking mechanisms, ensure they click securely into place.

Once all connections are reestablished, conduct a thorough review of your work. Confirm that each wire is connected to its corresponding terminal and that there are no exposed wires or loose connections. This careful inspection will help prevent potential issues in the future.

After ensuring that all electrical connections are secure, you can restore power to the system. Switch on the main power and test the 2000-1817.45 to confirm its proper functionality. Be attentive to any unusual noises, vibrations, or performance issues that could signal a problem with the installation.

By adhering to these steps for precise positioning and alignment, secure mounting, and careful reconnection of electrical systems, you can successfully install the new 2000-1817.45 component. This meticulous process will help ensure the optimal performance and longevity of your system.

FAQs

1. What tools do I need to install the 2000-1817.45 component?

You’ll typically require basic hand tools such as socket wrenches, screwdrivers, pliers, and possibly a torque wrench for tightening fasteners. Additionally, you may need electrical tools like wire strippers or crimpers.

2. How can I tell if the 2000-1817.45 component needs to be replaced?

Signs include leaks, unusual noises, reduced performance, increased vibration, and visible wear such as cracks or corrosion. Regular inspections can help identify these issues early.

3. Is it safe to reconnect electrical connections without turning off the power?

No, it is crucial to turn off the power at the main service panel before working on electrical connections to prevent electric shock and potential damage to the component.

4. What should I do if the component feels stuck during removal?

If the 2000-1817.45 component is stuck, try gently wiggling it to loosen it. If corrosion or buildup is the issue, applying penetrating oil and allowing it to sit for a few minutes can help.

5. How do I ensure proper alignment during installation?

Use reference points from the old component’s position and take measurements between specific points on the new component to verify alignment. Adjust as necessary to maintain proper caster, camber, and toe.

6. What should I check after installing the new component?

After installation, verify that all electrical connections are secure, that the mounting hardware is tightened to the manufacturer’s specifications, and test the component for proper functionality. Look for any unusual noises or vibrations.

Conclusion

Installing the 2000-1817.45 component requires careful attention to detail and a systematic approach. From safely disconnecting electrical systems to ensuring proper alignment and secure mounting, each step plays a vital role in achieving optimal performance and longevity of the equipment. By following the outlined procedures and maintaining vigilance during the installation process, users can effectively enhance the reliability of their systems. Moreover, regular inspections and maintenance will help identify potential issues before they escalate, ensuring smooth operation for years to come. Always refer to the manufacturer’s guidelines and prioritize safety to achieve the best results in your installation endeavors.

Stay in the loop for upcoming updates and alerts! The Verge Blog